Air Purity is critical for many operations. When purchasing a new compressor, one of the biggest questions should be, “What are the consequences of contamination in my application?”

Although both oil flooded and oil free compressors operate similarly, the distinction in air purity may be a fundamental differentiator. Oil lubricated compressors use oil in the compression chamber to act as a lubricant, sealant, and coolant, which can sometimes result in oil carry-over. Oil free compressors do not use oil in the compression chamber and instead often use timings with very tight tolerances between the rotor lobes, so there is no oil entering the air stream. Because compressed air comes into direct or indirect contact with products being manufactured, many industries have zero tolerance for the introduction of oil into the end product. And, in many operations, even a trace amount of oil could have detrimental effects.

Using oil free compressors could help save you from:

- Endangering the health and safety of customers

- Equipment damage

- Unplanned downtime

- Unforeseen financial costs

- Harm to brand reputation

There are many advantages to choosing an oil free air compressor. Using oil free technology helps ensure the quality of the end product by helping to eliminate potential contamination, is suitable for most applications, and helps manufacturers meet industry regulations by providing air purity where clean air is essential.

It’s no wonder oil free air has become a critical component of industries such as pharmaceuticals, food and beverage, electronics, high-technology manufacturing, textile manufacturing, packaging and many more.

Understanding Oil Free Air

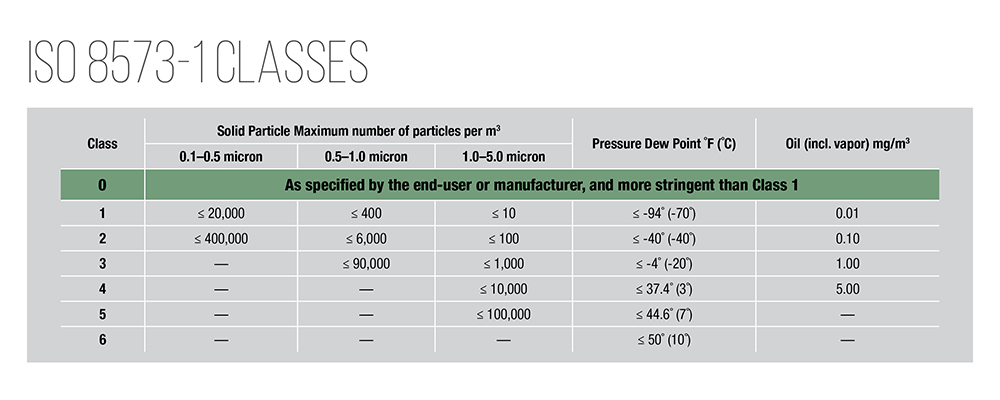

The International Standards Organization (ISO) has outlined a clear definition for air quality using the ISO 8573.1 Air Quality Classes for compressed air. Degree of air purity required varies based on the process and crossover risk associated. The lower the Class, the lower the concentration of oil contaminant is in the compressed air and the lower the risk of other contaminants.

Air quality is broken down into six air quality classes of three contaminant types: solids, humidity and liquid water, and oil. Solid particulates (like dust or pipe scale) can be removed by filters. Humidity and liquid water can be removed by compressed air dryers. Oil (liquid and vapor) can be removed by coalescing oil removal filters and activated carbon (charcoal) oil vapor adsorbing filters.

Oil free applications always require Quality Classes “1” or “0” for total oil concentration. Less than 0.01 mg/m³ (Class One) is the most common specification.

If a plant wants to specify a lower oil concentration – then the specification is Class 0. It is important to account for both liquid and vapor when designing the compressed air system. Not only must liquid oil be removed, but oil vapors must also be accounted for.

Learn how to read and understand the ISO 857.31 Air Quality Classes.

It’s important to make the right choice when selecting an air compressor – your business depends on it. And when air purity is critical, an oil free air compressor will help improve your operation, profitability, and peace of mind by reducing risks.

Learn how Oil Free Air Helps Ensures Reliability and Productivity

These are all important points to discuss with your authorized Sullair distributor when selecting and maintaining your air compressor. Refining these details will enable you to choose from the specific range of compressors best suited to your requirements. Sullair and its distributors are trained to deeply explore the unique needs of our customers. A collaborative approach between the teams ensures a comprehensive understanding of the function required for the specific application. Our focus is on designing fit-for-purpose solutions that deliver the most suitable product with the right pressure, air flow, and quality, to meet your requirements today and beyond. If you have questions, please contact us.